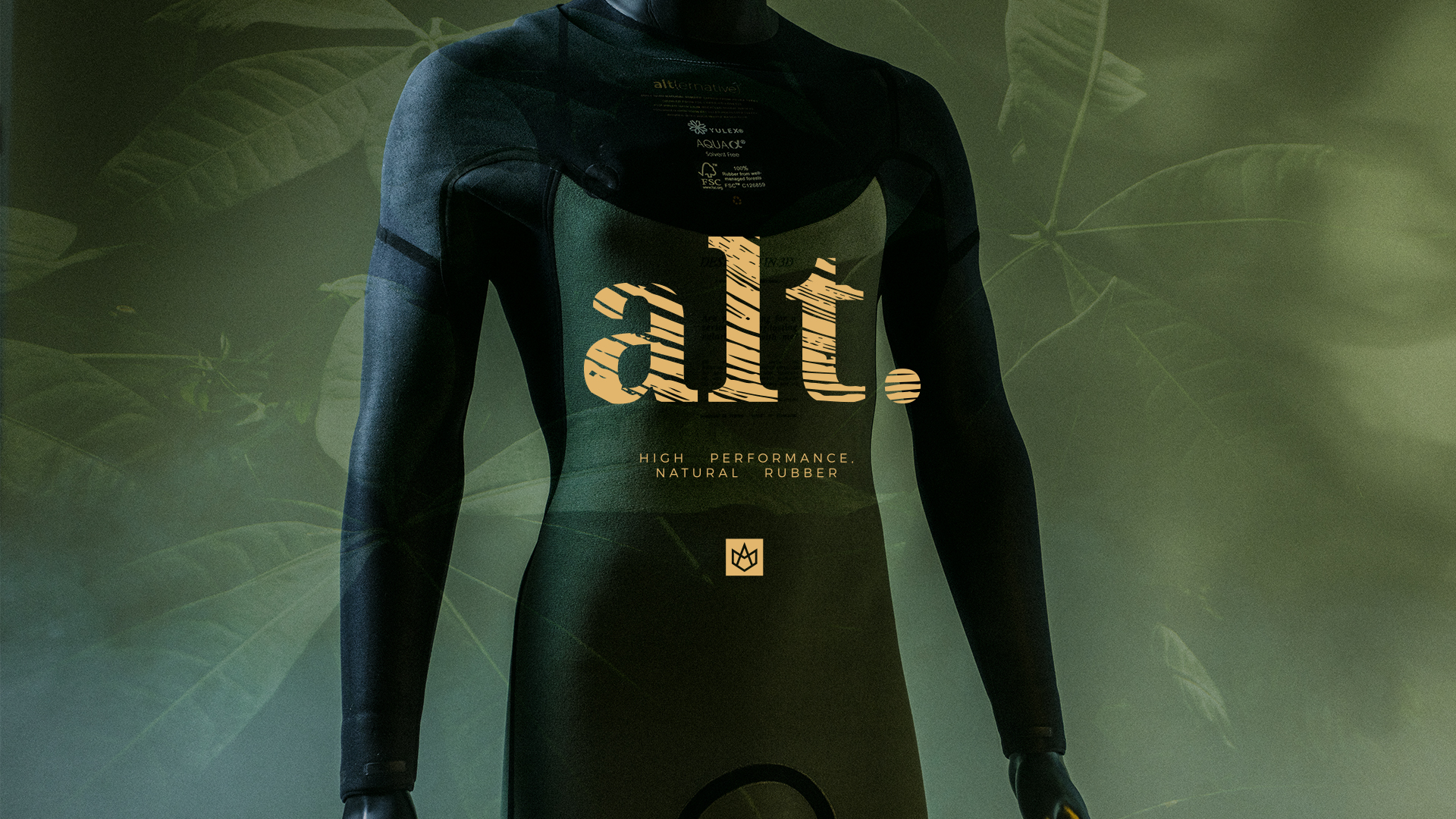

The MANERA ALT range offers a more sustainable alternative to conventional wetsuits with performance in mind.

Each ALT wetsuit — ALT standing for Alternative — is made from 100% natural Yulex rubber, sourced from responsibly harvested tree forests, hence reducing our reliance on non-renewable energy sources.

Traditional neoprene vs. Yulex

Traditional neoprene is manufactured in two main ways. The first, based on petroleum, uses polymerized derivatives to produce chloroprene chips which, when heated to high temperatures, become neoprene. Nowadays, water and sulfur are also added to produce large sheets of neoprene, which are then cut to make wetsuits.

The second, slightly more ecological method uses limestone to produce “limestone” neoprene. Although less energy-intensive than the petroleum-based version, this process still requires a lot of energy to drill, crush and heat the limestone.

Since 2016, Yulex has offered the first alternative to the traditional neoprene wetsuit, through a natural rubber alternative extracted from hevea trees. The Yulex process is undergoing constant innovation, and now boasts quality, flexibility and resistance equivalent, if not superior, to traditional neoprene.

What is Yulex ®?

Yulex® is a natural plant-based rubber that provides an alternative to traditional petroleum or limestone-based neoprene.

The Yulex company partners with FSC-certified Hevea tree plantations to harvest tree latex, then uses its unique process to transform it into a pure solid natural rubber.

- Renewable

Unlike finite resources like oil and limestone, natural rubber is a renewable resource. Directly tapped from Hevea trees without cutting them down, it ensures a long-term supply stability as well as a drastically reduced environmental impact. - Reduced water consumption

A ton of Yulex requires 25,000L of water to be produced, while limestone-based neoprene necessitates more than 10 times that amount. Moreover, Yulex recycles wastewater by re-using it during the production process. - Reduced energy consumption

One ton of Yulex requires 1,150kwh to be produced when limestone-based neoprene demands more than 29 times that amount. - Reduced carbon footprint

Yulex claims that using their natural rubber rather than traditional neoprene reduces the carbon footprint of our wetsuits by 80%. - CO2 emission to produce 1 kg synthetic vs. 1 kg of natural rubber :

- Synthetic Rubber = ~3,000 kg CO2e emitted

- Natural Rubber = 0 kg CO2e emitted. Mother Nature makes the best polymers !

It’s no secret traditional neoprene is not good for the environment, so anything we can do to get away from it is great. What makes Yulex natural rubber truly stand out is that it no longer requires choosing between performance and environmental responsibility.

We take pride in working to find solutions to make products that are more environmentally sustainable. It is our goal and hope that, one day, the whole wetsuit market will make neoprene a thing of the past.

Find out more on the MANERA ALT wetsuit range, available in 5.4.3 and 4.3.

*all data is courtesy of Yulex®.